Recycling is a complex system made up of legislative regulations, market demand, processing costs, the success of which depends on everyone from the product designer, to the person who throws in the bin, the waste collector, to the factory worker. recycle. We as consumers have a much more valuable role to play than we might imagine—how we use products and how we dispose of them determines their value and quality after use. Think about it – products made from recycled materials have to compete with new products on the market; who wants to buy something of inferior quality?

For many, waste management starts with the recycling symbol and ends with the recycling bin. The simple act of tossing something into a large bin marked with the recycling symbol is enough to make some of us feel like we've done our duty. We believe in the magic of the recycling bin that it will take care of the rest of the recycling process. But recycling is much more complicated, and the process of recycling plastics is important and necessary to do correctly.

Plastic recycling is a concept that emerged in the 1960s and 1970s when concerns about plastic pollution arose. But the problem is that plastic cannot be recycled forever. Its value and resistance decrease each time it is recycled. In addition, there are plastics that cannot be recycled, and recycled plastic has limited options for use due to safety concerns. Many people are discouraged when they want to implement a selective waste collection system at home, school or work. They realize that of all the plastic packaging and products they want to recycle, only a small percentage can be recycled. There are several reasons for this. First of all, PLASTIC is not just about one material. This word refers to various synthetic or semi-synthetic materials with similar qualities: light, durable, flexible, and most importantly, with a flexibility that allows them to be molded, extruded, or pressed into solid objects of various shapes. Despite the similarities, plastics differ in properties: one material can be extremely hard, while another can be thin and flexible enough to be cling film for example. But more importantly, different types of plastics have different melting points, meaning that while one plastic won't be affected by heat, another will melt or even burn.

Here are the 7 types of plastic we deal with in our everyday life and how they can be recycled correctly:

Polyethylene terephthalate – PET

Water bottles and juice bottles are examples of items made from PET. This is the easiest type of sorted and recyclable packaging. These types of bottles are sometimes collected by local authorized waste collection operators. Thanks to this recycling system already applied in practice, up to 90% of bottles can be collected and recycled (a practice found in Estonia, Germany and Sweden, for example).

High Density Polyethylene – HDPE

Due to its durability and rigidity, this material is particularly suitable for containers of detergents and chemical products. It is also used to produce speakers, covers, technical items, household items, auto parts, toys and furniture pieces. This type of plastic often contains residues (pigments or additives) from its previous use that can affect the quality of the recycled product. However, recycled HDPE has many uses. Today's sorting and recycling technologies allow a large proportion of HDPE packaging to be recycled, as long as it does not contain foreign elements that complicate the process.

Due to its durability and rigidity, this material is particularly suitable for containers of detergents and chemical products. It is also used to produce speakers, covers, technical items, household items, auto parts, toys and furniture pieces. This type of plastic often contains residues (pigments or additives) from its previous use that can affect the quality of the recycled product. However, recycled HDPE has many uses. Today's sorting and recycling technologies allow a large proportion of HDPE packaging to be recycled, as long as it does not contain foreign elements that complicate the process.

Polyvinyl chloride - PVC

PVC is widely used in the packaging sector, cosmetic containers and bottles, labels and blisters. It is also widely used in the construction industry, including for the production of exterior materials and components such as flooring, construction pipes (such as gutters and water pipes), window frames, tarpaulins and rigid films. PVC is also widely used in the medical and hospital sector, in the chemical, automotive and agricultural industries. It is rarely recycled because creating a recycling system for this type of plastic is a complex and quite expensive task.

PVC is widely used in the packaging sector, cosmetic containers and bottles, labels and blisters. It is also widely used in the construction industry, including for the production of exterior materials and components such as flooring, construction pipes (such as gutters and water pipes), window frames, tarpaulins and rigid films. PVC is also widely used in the medical and hospital sector, in the chemical, automotive and agricultural industries. It is rarely recycled because creating a recycling system for this type of plastic is a complex and quite expensive task.

Low density polyethylene – LDPE

Plastic bags are an example of an item made from LDPE. This plastic loses its transparency during recycling. It is a plastic resistant to both high and low temperatures. Code 4 appears on certain types of bottles, in frozen food bags or on cutlery. This type of plastic can be thrown in the plastic recycling bin. Recycled LDPE can be made into products such as: tiles, postal envelopes, furniture, bins and compost, etc.

Plastic bags are an example of an item made from LDPE. This plastic loses its transparency during recycling. It is a plastic resistant to both high and low temperatures. Code 4 appears on certain types of bottles, in frozen food bags or on cutlery. This type of plastic can be thrown in the plastic recycling bin. Recycled LDPE can be made into products such as: tiles, postal envelopes, furniture, bins and compost, etc.

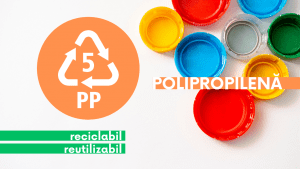

Polypropylene – PP

PP is used for various products such as reusable plastic food containers, lids, ropes, ice cream wrappers and certain toys. Manufacturers prefer to use polypropylene because it is lightweight and durable, but also offers good protection against moisture or chemicals and is resistant to high temperatures.

PP is used for various products such as reusable plastic food containers, lids, ropes, ice cream wrappers and certain toys. Manufacturers prefer to use polypropylene because it is lightweight and durable, but also offers good protection against moisture or chemicals and is resistant to high temperatures.

PP is recyclable and PP packaging can be reused due to its durability and safety.

Type 6 – Polystyrene – P.S

Polystyrene has many different areas of use, especially in the individual packaging of items and in the production of disposable containers for fast food, office supplies, etc. Polystyrene grew in popularity once it was realized that it was light and rigid. In foam form, polystyrene is light because it consists of 95% air. It is also versatile and inexpensive. Polystyrene is also used to make hard plastic items and plastic wrap. In its rigid form, polystyrene is brittle, for example expanded polystyrene (EPS) is a polystyrene product widely used in construction. PS is not recycled nor can it be reused.

Polystyrene has many different areas of use, especially in the individual packaging of items and in the production of disposable containers for fast food, office supplies, etc. Polystyrene grew in popularity once it was realized that it was light and rigid. In foam form, polystyrene is light because it consists of 95% air. It is also versatile and inexpensive. Polystyrene is also used to make hard plastic items and plastic wrap. In its rigid form, polystyrene is brittle, for example expanded polystyrene (EPS) is a polystyrene product widely used in construction. PS is not recycled nor can it be reused.

Other plastics – OTHER/0

Marking 7 is used when a plastic product does not fit into any of the numbers 1 to 6. It is basically a general category for all types of plastics other than numbers 1 to 6. The category includes plastics recyclable, non-recyclable and biodegradable. The marking can be seen on disposable cutlery, CD/DVD, clothes, LCD screens, kitchen sponges, etc. Such plastic is not collected and recycled by local recycling operators because it contains a wide variety of plastics, which are difficult to collect and recognize at the sorting center.

Marking 7 is used when a plastic product does not fit into any of the numbers 1 to 6. It is basically a general category for all types of plastics other than numbers 1 to 6. The category includes plastics recyclable, non-recyclable and biodegradable. The marking can be seen on disposable cutlery, CD/DVD, clothes, LCD screens, kitchen sponges, etc. Such plastic is not collected and recycled by local recycling operators because it contains a wide variety of plastics, which are difficult to collect and recognize at the sorting center.

In plastic production, energy is the resource with the largest share, representing 72-91% of the total resource requirement of this material. The production of recycled plastic products consumes less energy than plastic obtained from primary raw materials: PET with 62-92% and HDPE with 77%. But if the foil and other light packaging is contaminated with biological waste, recycling cannot be done.

How can YOU become an example in plastic recycling?

While manufacturers bear the responsibility for designing recyclable items, governments are responsible for allowing such products to be produced and sold, and YOUR part of the responsibility lies in the choices you make.

Here are some tips on how you can honor your duty to the environment when it comes to plastic pollution:

- Avoid plastic packaging and products. If the first step is impossible, choose:

- Plastic packaging that is not colored or does not have large labels that cover the entire surface;

- Packaging containing a single material (glass, paper, metal, a type of plastic);

- Recyclable plastic packaging such as PET or HDPE;

- Carefully study the recycling instructions;

- Prepares plastic for recycling according to instructions (rinse and compress);

- Dispose of recyclable plastic only in the dedicated plastic waste bin.